Sunday August 21, 2016 Guerneville CA.

Would I get the new engine started today

I was thinking when I started working on the van engine project this morning that I might get the new engine started today, but as I continued to work on things, I decided to just keep puttering along and go with whatever worked out as rushing things at this point just didn’t seem to be a good idea.

Wiring harnesses

The first thing I did today once I got started was to finish off the main wiring harness. There were a few more wires to tuck in and the TBI wiring harness needed to be integrated with the main harness. I used a lot of cable ties to dress it all up and secure things to keep them from being damaged.

TBI controller is hooked up

After I got that all buttoned up, I finished hooking up the main computer that runs the TBI. A TBI is just an injector that is used on modern engines instead of a carburetor and needs a computer to control it and lots of sensors too, so it means there are lots of wires to run, which were all in a special wiring harness that came with the kit from Howell Engine Industries.

Routing spark plug wires

Then I spent some time routing and rerouting the spark plug wires trying to get the best ones in the best places as far as length went. The wire holders really helped out a lot and I think I’ll buy some more of them.

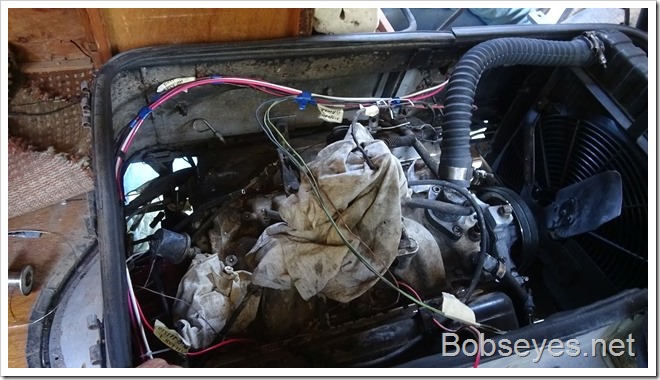

Here’s a picture from the back of the new engine, almost ready to go.

Spark plug wires down the back and around the side

Running the spark plug wires down the back of the engine and up along the sides gives this a cleaner install I think as compared to coming over the top of the hot manifolds. When the engine cover is put on there isn’t much room to get the wires over the top without them tending to get on the hot exhaust manifolds. That oil dip stick isn’t going to work either as the engine cover will cover that spot, so something needs to be done to it too.

Being creative with the radiator overflow tank

But for now I needed to do something with the radiator overfill tank which I decided to make out of a gallon radiator coolant plastic bottle as it was all I could think of to fit the spot for now. As it was I had to heat the top and crunch it a bit to get it to fit. This picture shows the gallon jug inside another bottom of an oil jug to give it some protection from the metal parts it’s sitting on. It’s not strapped in yet either.

Re-strapping

I couldn’t get the strap through the strap holes I made in the bracket and installed back in that spot, so I pulled the bracket off and welded another buckle toward the middle of the bracket and could now thread the strap on which also meant that the strap that was too short to work before was now just long enough to work. I installed the strap and tightened up the bottle which looked like this back in it’s little spot.

I had cut the plastic handle off the jug so I put the hose in that hole with a piece of steel pipe going through a larger cap off the oil jug which just sits there with the pipe holding it in and not falling out. The pipe is in the back there and goes to the bottom of the tank. You can see this unit is rather stuffed in that spot.

That should work out at least for now and maybe a lot longer too, unless I can figure out something more elegant.

Out of steam

It was getting late and I was running out of steam, well actually, I ran out of steam a long time ago and not sure what I was running on.

The oil dip stick proved to be too much

That darn oil dip stick. Seems like such a simple thing to be causing such a big problem. I decided to do some bending on it. But the bends have to be real gradual or the oil dip stick won’t go through the tube, so I started bending a little at a time, then checking it and bending a little more. I need to bend it to the back rear and then up to clear the engine cover that will be installed.

Rib cramps ouch

I worked on that until I started getting some rib type cramps which hurt, but are also more worrying because of where they hurt. I’ve had some of these before, so was pretty sure what they were, but it’s not something you can be real sure of, for sure. It was being caused from me trying to get this older body to bend that pipe in small increments. In other words, I used a bunch of muscles that don’t get used like that very often these days.

Giving it up for the day

The end result was I got the tube bent some but had to give it up for now and besides it was starting to get dark.

I did study the new store bought throttle cable I need to install and think I have some ideas on how to do that without too much trouble.

Let’s see, put some water in the radiator and check everything out again and hook up the battery and I think I’m ready to fire up the new engine after I get the new throttle cable installed first.

Productive day.