Friday April 5, 2024 Guerneville CA.

Bumper work

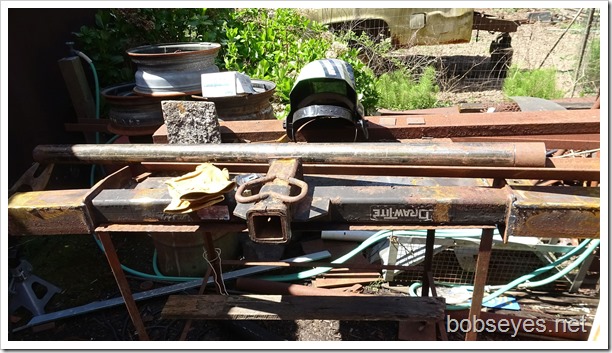

I wasn’t sure what I wanted to do today. Going up into the forest was my first choice, but instead I worked on the pipes for the bumper for Skiddy.

This pipe was two inches too short so I cut another piece two inches long to weld to it.

I welded the two inch piece up in this setup.

And cut some metal for end caps and welded them on both ends of the pipe.

A bit of grinding to finish up the end and this piece of pipe was ready to go for the bumper.

Butterfly

I was taking a break when I saw something flutter over on the chicken house so I went over to see what it was. A black butterfly. These ones are attracted to my California Dutchman’s pipe plant as their caterpillars love to eat it. This is one of the larger ones of these I’ve seen.

Now for the hard part of pipe joining

Tom made me a template to make the special end on the pipe to join it to another pipe.

I used the template but was having trouble making the pipe fit properly to the other pipe.

That meant I had to do a lot of grinding on the pipe to make it fit. which I did.

I went over to talk to Tom about the bad template and he decided he likely had forgotten the proper measurement and he made me a new template that should work better for the next pipe.

This is the one I made by grinding it a lot and it fits pretty good.

All that grinding I did to make the pipes fit wore me out so enough of that for now.

I spent the rest of the day finishing up the 2nd. bridge I was making, doing some more welding on it and got it all done.

Nice day.